What is OIS (Optical Image Stabilizer)?

Development Item Summary

AF ACTUATOR Summary

AF moves the lens up and down to the optimum focus position to ensure that an object appears clearly.

(In 2007, 2% is applied> In 2017, 78% is estimated.)

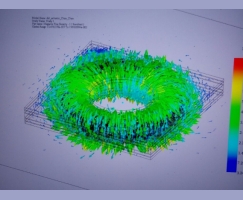

OIS ACTUATOR Summary

Optical image stabilization function - The user's hand tremor is detected according to the movement of the camera and the lens moves finely like a human eye, moving the lens in the opposite direction of the tremor, thereby, the image is prevented from shaking.

The OIS function is adopted to ‘iPhone 6+’, Samsung Electronics ‘Galaxy Note 4‘ since LG Electronics introduced OIS to 'G2' in 2013.

Because the difference in image quality is due to whether the OIS function is installed or not as the smartphone's high resolution progresses, 3% OIS adoption rate in 2014 has increased by 19% in 2017. OIS ACTUATOR is still limited with manufactures as it is difficult to secure yield and mass production.

OIS(Optical Image Stabilizer) 구현 방식

It senses the slight tremble of the hand using the exterior gyro sensor of the camera and compensates the focus by calibrating the coordinates of the lens, which shaking left and right.

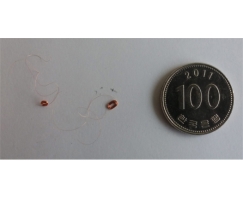

There are two ways to implement the OIS: shifting and tilting. Four enameled wires each having an ultra-fine diameter of 35 to 40 μm are coiled and soldered 80 to 100 times in the form of an elliptical loop and solder.

All VCM ACTUATORs around the world use 100% enamel coils. All processes (fabrication/ inspection) except for the winding process are manual using microscopes. Due to the characteristics of ultra-small diameter enameled wire in mass production, defect rates are extremely high in winding wire, soldering, and foreign matter.

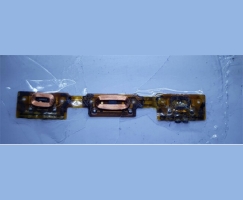

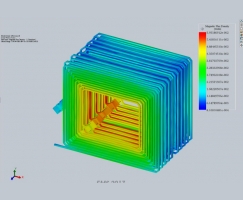

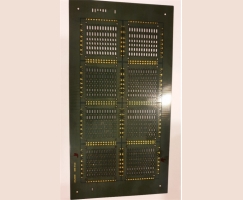

We endeavor to develop methods to secure technological and business competitiveness by changing materials, simplifying manufacturing processes, minimizing defect rate, and automating production. In addition, we are initiative in solving the problems by using multi-layer printed circuit board (M-PCB) pattern coil and modularization for automation.

Technology Development and Implementation

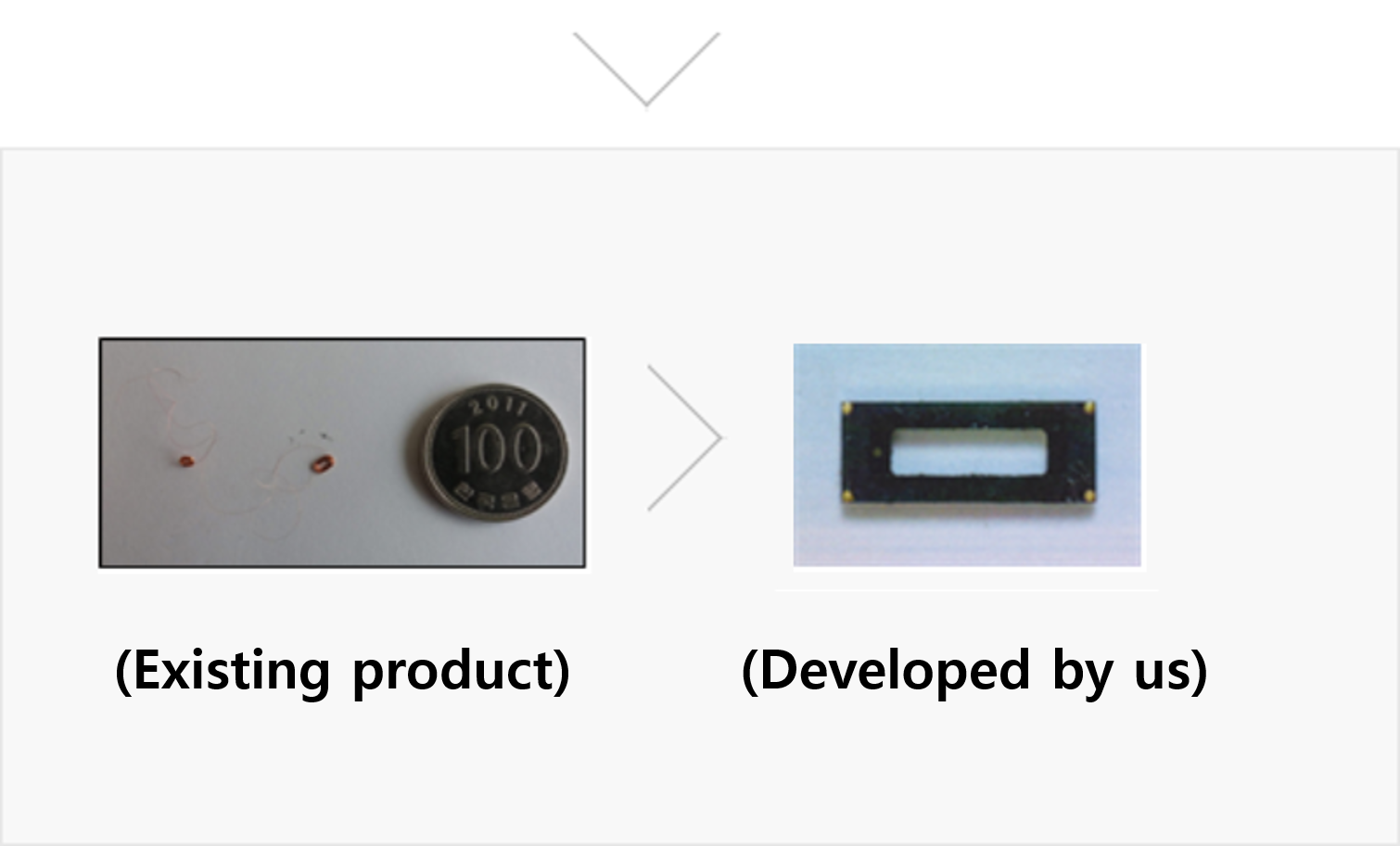

Substitute material

Enamel Coil > "PCB Pattern Coil" to eliminate the source of the original defect.

The current method of manufacturing VCM actuators is to use enameled wire having a diameter of 35 to 40μm. It is made by winding, and due to the characteristics of ultra-small diameter enameled wire, it is considered that the winding is bad, the disconnection is bad, the soldering is bad,100% of them all contain fundamental problems that can not be solved.

In addition to the manufacturing process as well as the inspection process, it is imperative that the process of passing the inspection by human beings

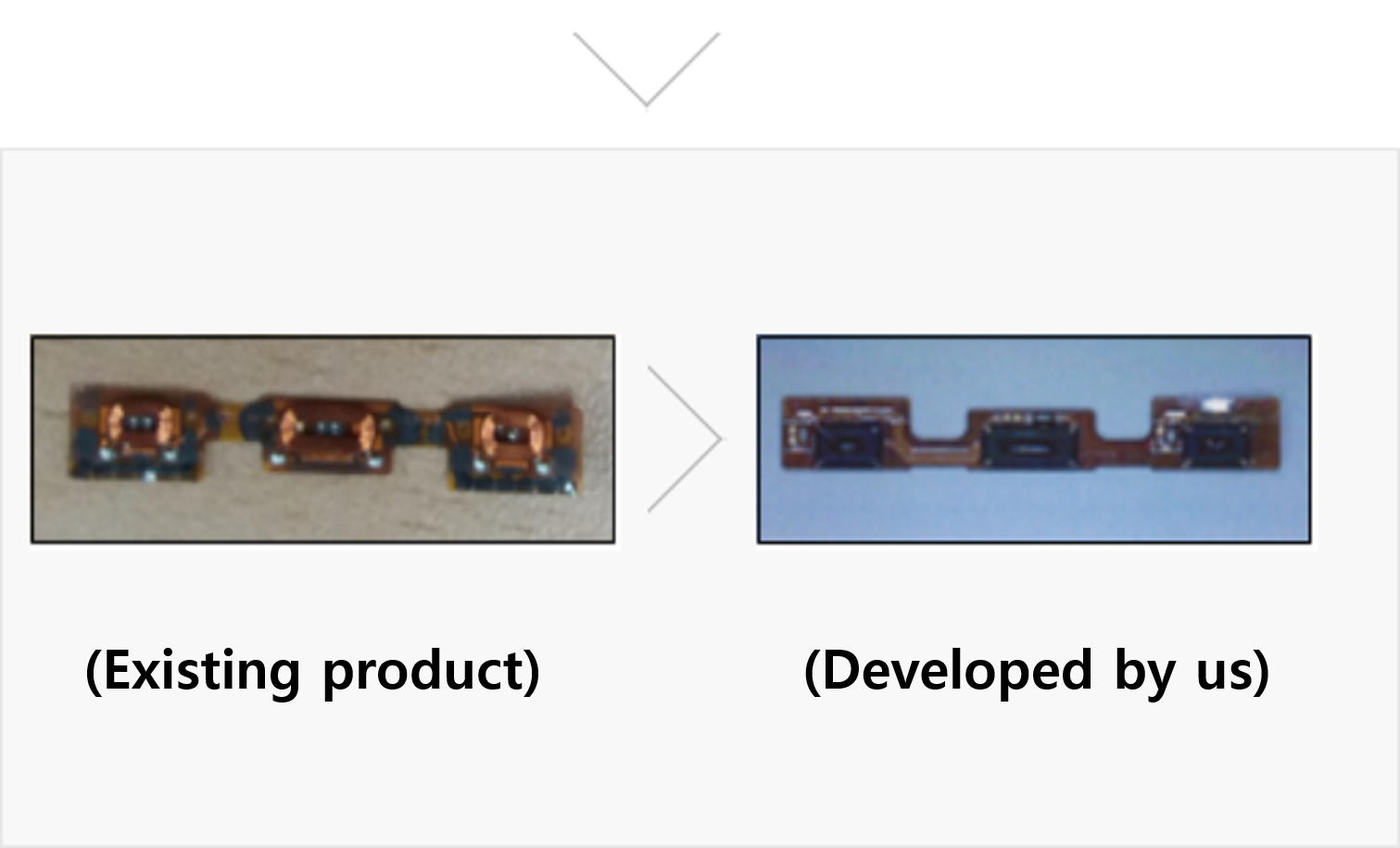

Process change

Handwork > Decrease in production costs due to production automation by "modularization"

As a technical attempt to solve the above problems, the technology proposed a PCB pattern coil of a multi-layer printed circuit (M-PCB) method and a modularization method for automation, Because it is possible to mass-produce, it is a technology development to solve the problems of rising cost and defect rate due to the existing manual work (Technical Influence) : It is expected that the technology will be applied to all parts using cameras such as autonomous vehicles, drones, and medical equipment as well as smart phones

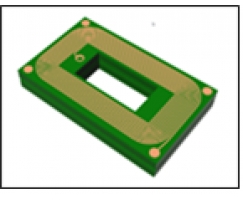

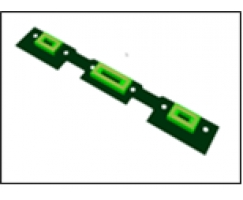

Products

CAMERA MODULE

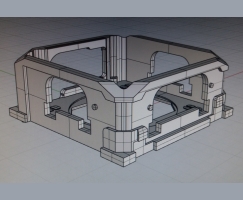

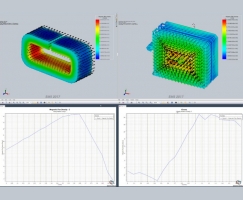

SIMULATION

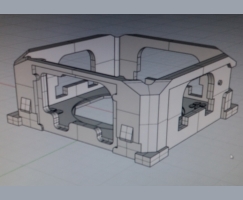

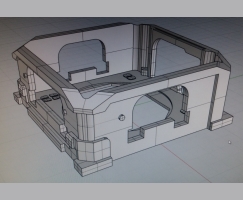

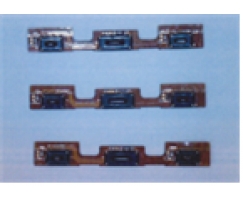

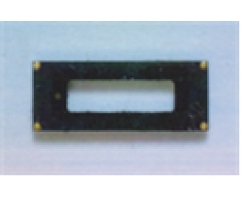

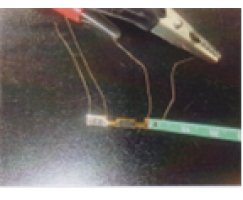

PROTOTYPE

ASSEMBLY

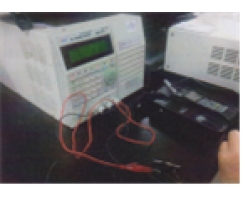

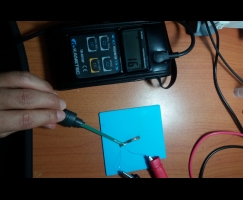

MEASURE

PROTO SAMPLE

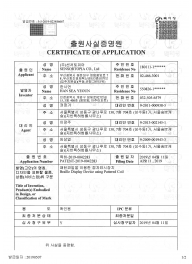

Patents

10-20072070219.07.30

Positioning board assembly for camera module, and a manufacturing method thereof and a camera module comprising the same

10-2019-00422832019.04.11

Braille Display Device using Patterned Coil